What You Need to Know

Whether you live, work, or travel near the bridge, we want you to know what to expect and what we’re doing to minimize disruptions.

- Work Hours: Construction activity will typically occur Monday through Saturday during daylight hours within a 12-hour window.

- Noise & Vibration Monitoring: Monitoring equipment is being used in nearby communities to provide real-time feedback to the construction team and help minimize disruption.

- You Will See: Large equipment, construction crews, and increased activity on land and in the water.

- You May Hear: Noise typical of large construction projects, and loud, repetitive hammering sounds from pile driving.

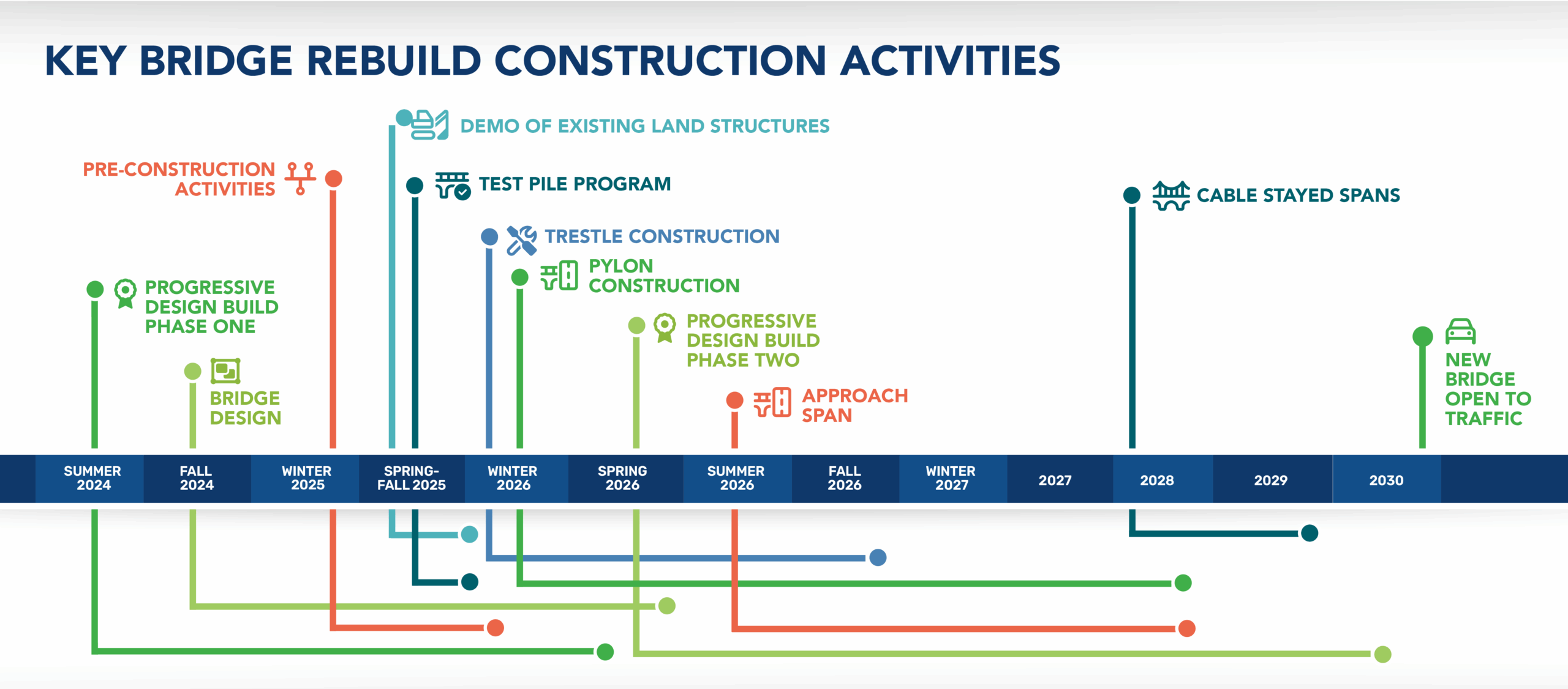

Construction and Ongoing Activities

Explore the major pre-construction activities driving progress as we work to rebuild the Key Bridge.

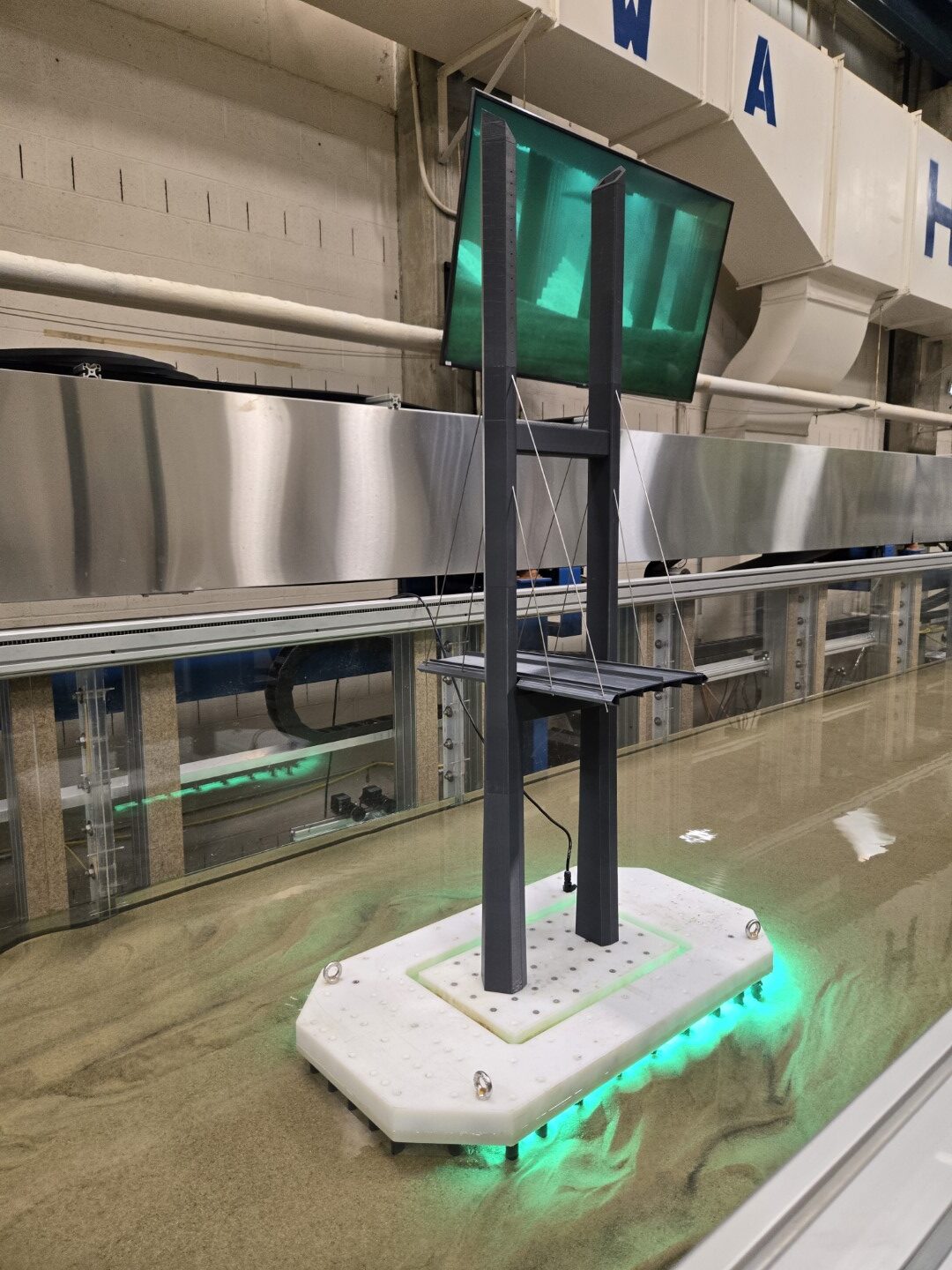

Wind Tunnel Testing

- Engineers simulated conditions to study how the bridge responds to various wind loads.

- The bridge’s cross section was tested based on wind and traffic patterns from the final design.

Survey & Mapping

Crews collected of topographic data using drone flights, right-of-way boundary surveys and subsurface utility mapping to support detailed design work.

Scour Testing

Specialists modeled water flow around the bridge’s foundation and support piles to assess impacts on the riverbed and ensure long-term structural stability.

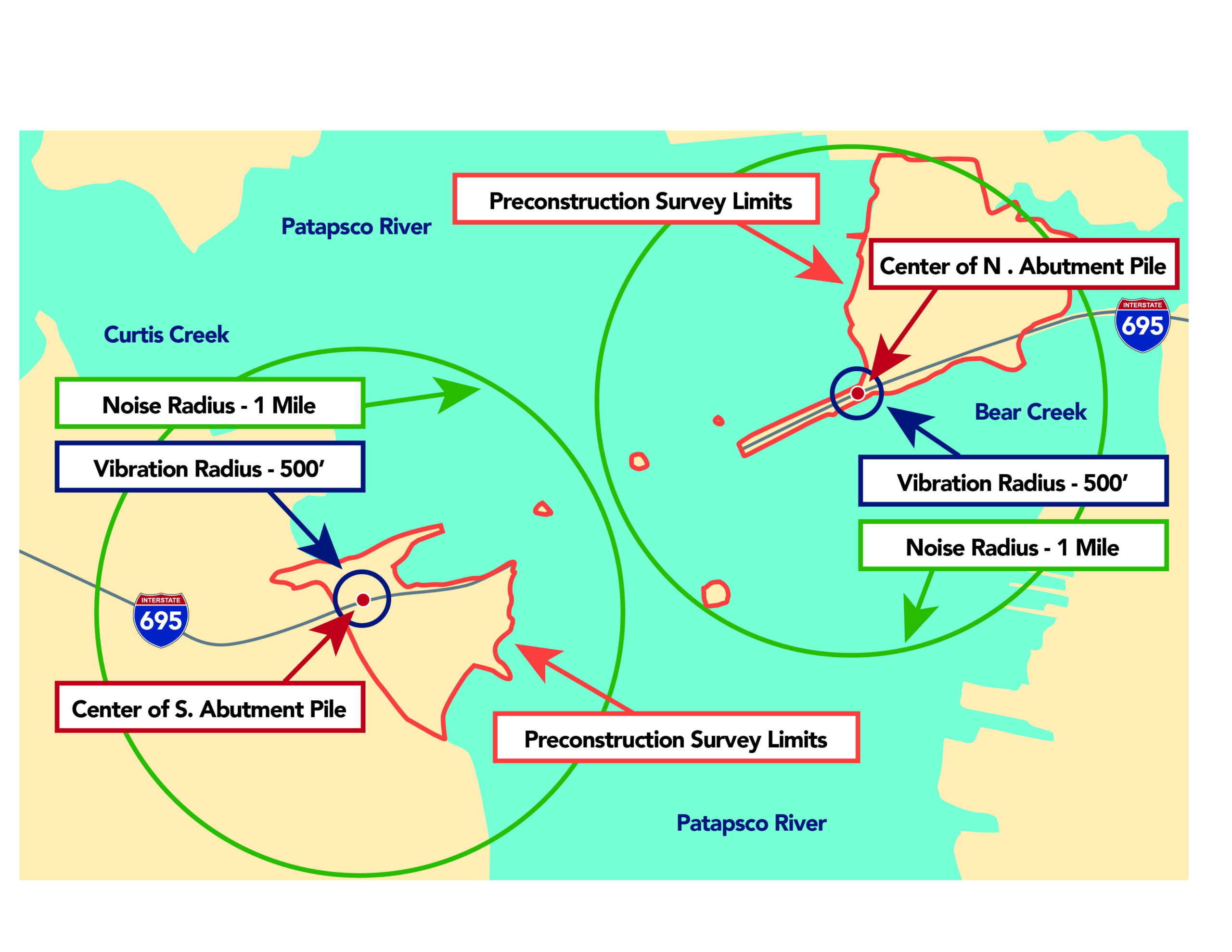

Property Inspections

- Teams completed 1,121 property inspections to document baseline conditions before major construction begins.

- Inspections covered properties within a 1-mile radius of the northernmost and southernmost pile-driving locations.

- Photo and video documentation during inspections captured pre-construction conditions of the properties.

Test Pile Fabrication

- Crews are fabricating test piles and load test frames for the upcoming pile load testing program, which supports the design of the bridge’s main span.

- Each test pile is built piece by piece, with the finished piles measuring 8 feet wide and over 200 feet long.

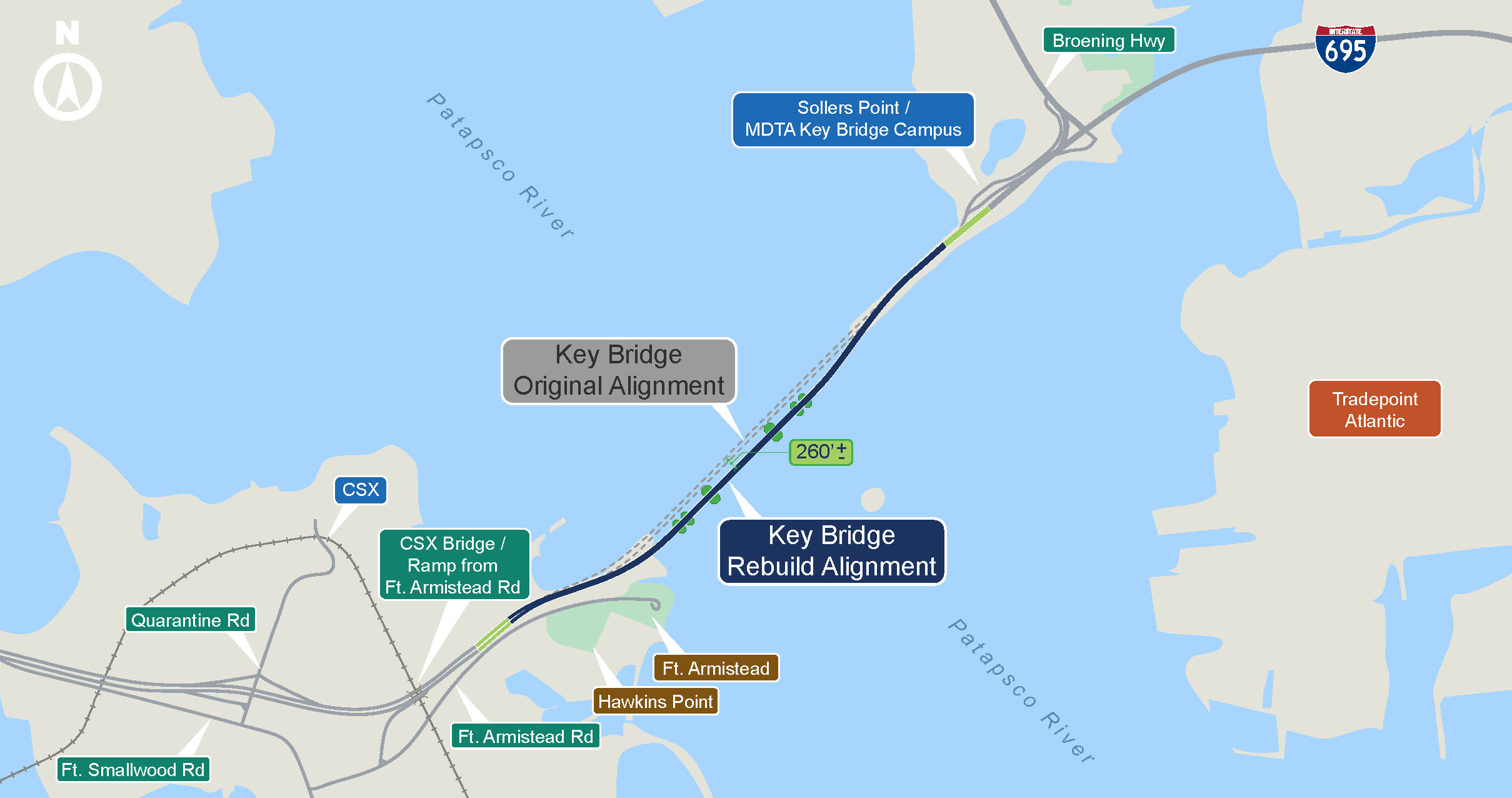

Bridge Alignment

- Based on months of field investigations and engineering analysis, the new bridge alignment was determined to be slightly east (downriver) of the original structure.

- The alignment remains entirely within MDTA’s existing right-of-way.

Geotechnical Investigations

- Engineers conducted extensive marine-based borings in the Patapsco River riverbed and land-based borings along the bridge alignment to evaluate soil conditions and support the pile and foundation design.

- Laboratory tests classified the soils found in the riverbed and on the north and south sides of the bridge.

- The geotechnical boring results identified the soil profile beneath the surface, helping guide the design of the bridge foundations.

Noise & Vibration Monitoring

- Monitoring equipment was installed in nearby communities to record baseline noise and vibration levels before demolition, test pile installation, and full construction begins.

- These baseline readings help define normal everyday conditions in the area.

- Ongoing monitoring during construction allows the team to track changes in noise and vibration and respond as needed.